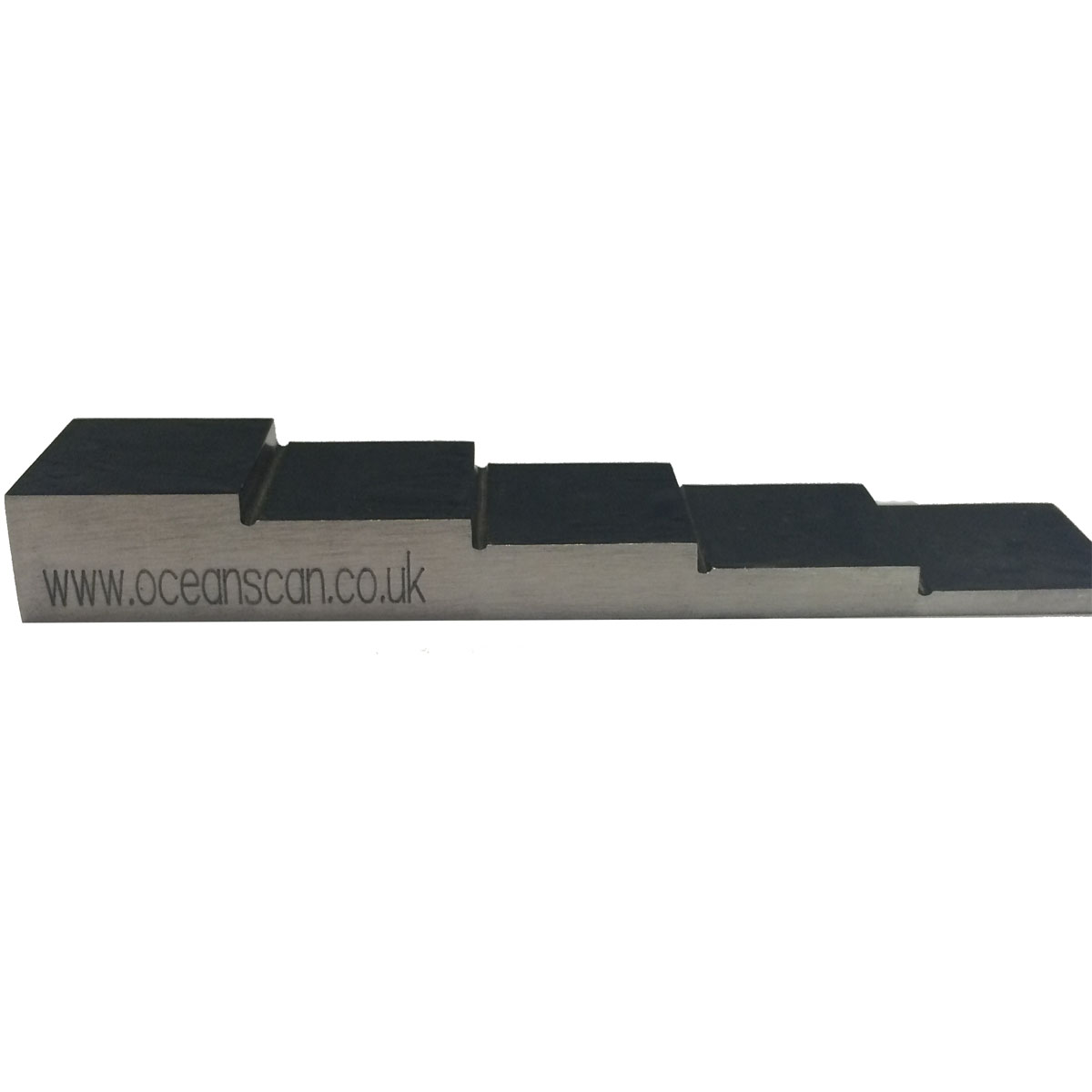

A 5 Step Block is a calibration standard used to calibrate ultrasonic testing equipment. It features five stepped surfacesof different known thicknesses, which help the technician check the performance of ultrasonic instruments. The stepped surfaces allow for the detection of defects by providing a set of known distances that can be used to verify the accuracy of the equipment’s readings. It is commonly used in industries such as aerospace, automotive, and manufacturing to ensure the accuracy and reliability of ultrasonic testing equipment.

Five stepped surfaces: Each step has a different known thickness, allowing for a range of calibration checks. Designed for use with ultrasonic testing equipment. Used to verify depth measurement and equipment accuracy. Made from durable materials like steel, ensuring long-lasting reliability and precision.Commonly used in calibration and maintenance checks for ultrasonic inspection equipment.

Reviews

There are no reviews yet.