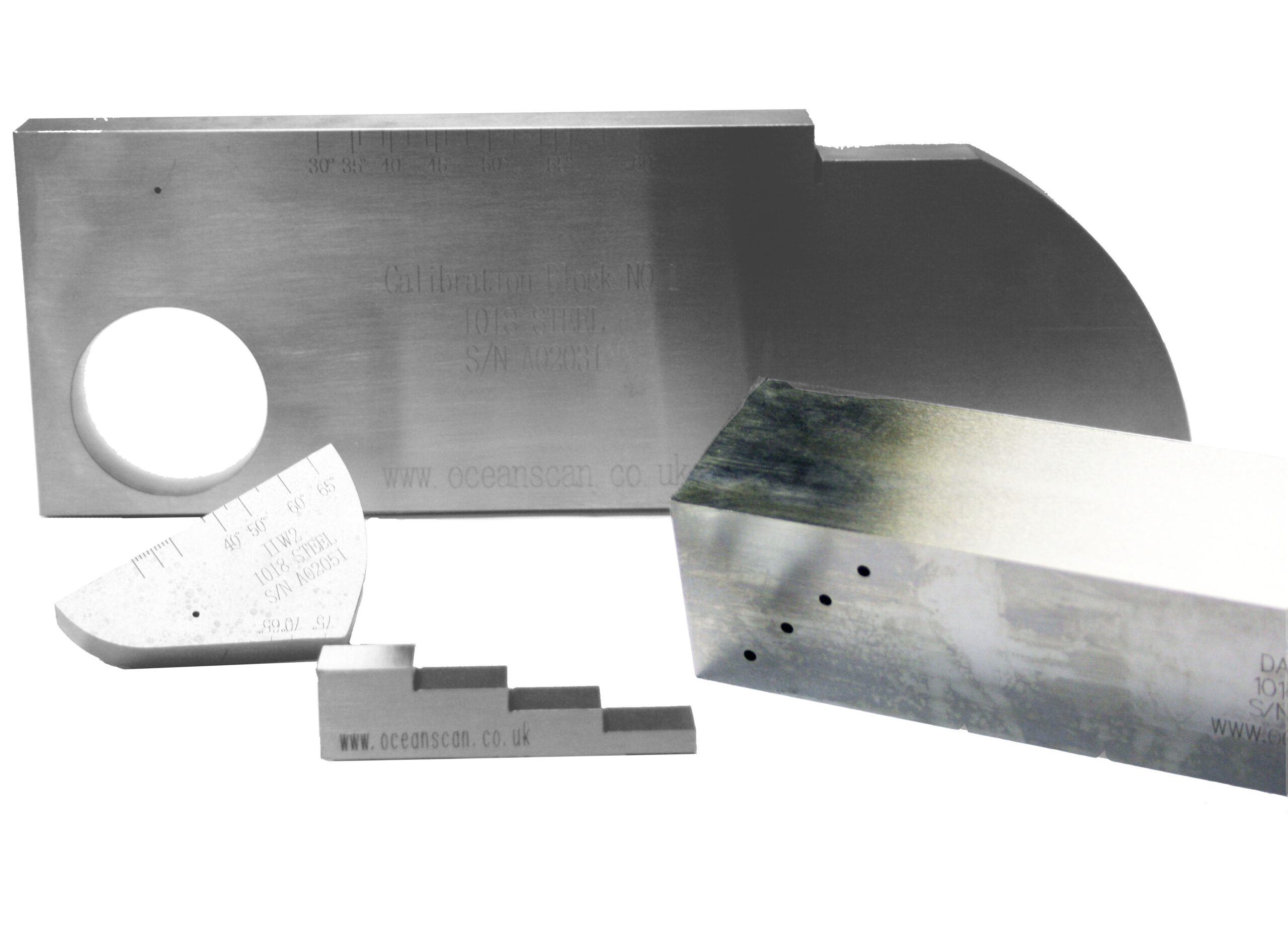

The DAC Test Block is a specialized calibration standard designed for ultrasonic flaw detection and distance amplitude correction (DAC). It is used to calibrate ultrasonic testing equipment to ensure accurate readings of distance and amplitude when inspecting materials for internal defects. The block typically features multiple step-like surfaces, each of which allows the operator to verify the sensitivity of the ultrasonic equipment over a range of distances and defect sizes. It is used for inspecting thickness, weld integrity, and cracks within materials.

Distance Amplitude Correction (DAC): The block helps calibrate equipment for accurately measuring the distance and amplitude of ultrasonic waves that reflect from flaws within materials.Multiple Reference Points: The block is often engraved with various reference points, such as step heights and angles, that allow the technician to verify the accuracy of the ultrasonic device at different settings.Material: Usually made from high-quality 1018 steel or other reliable materials for consistent performance and durability.Calibrated for ultrasonic equipment: Ensures that the ultrasonic system provides correct readings and accurate data during inspections of materials such as steel, aluminum, or composites.Used in routine checks: Provides reference points for routine testing and maintenance of ultrasonic equipment.

Reviews

There are no reviews yet.